Email Support

info@ir-pl.com Call Support

+91-9999-192-190

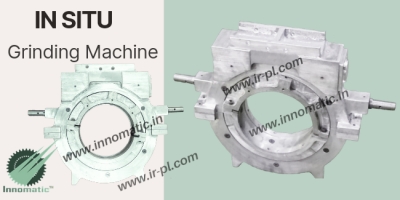

IRPL In-situ Crankshaft Grinding and polishing machine are develop by new production methods, optimize existing machines after we build new In-situ Crankshaft grinding machines and design testing of machine as per the international standards.

Through the years we have gained experiences in many different industries. We are design and built custom portable onsite crankshaft grinding and polishing machine. In case the If any cranks shaft damage only one or two crank pins, economics do not justify dispatch of entire crank shaft to a distant workshop. Our fine designed machine is suitable for In-situ grinding and polishing of 50 mm - 600 mm diameter crank pin without dismantling or removing of crankshaft from the engine block. You can easily grind and polish through inspection window of the engine block. Due to compact in size and portable it’s able to enter from inspection window of any size of block.

On-situ Crankshaft Grinding machine easily set up on the crankshaft requiring repair simple techniques to ensure correct alignment and accuracy. We can also provide training and manual for operating our machine accurately after purchasing of In-situ Crankshaft Grinding and polishing machine.

Technical Specification of In-situ grinding machine

Benefits of IN-situ crankshaft grinding machine

Application Area of on-site crankshaft polishing machine